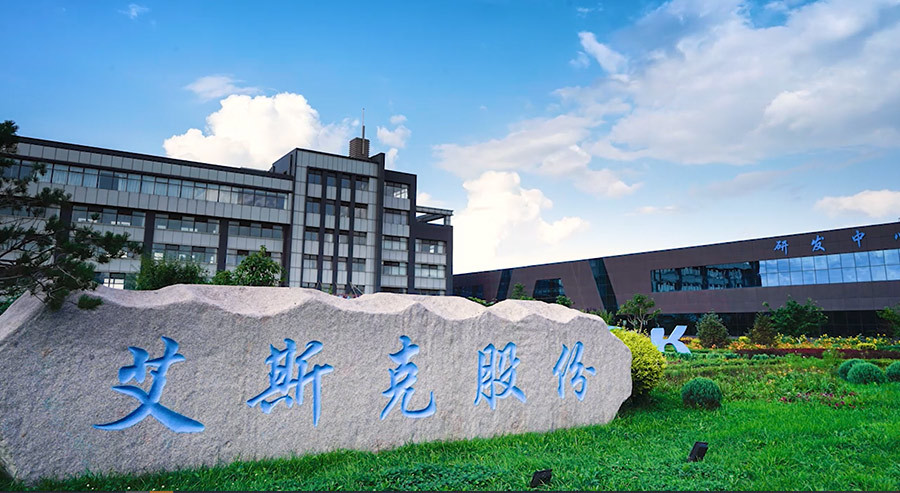

Company Profile

Jilin SSK Electromechanical Co.Ltd.

ADHERE TO SCIENTIFIC AND TECHNOLOGICAL

NNOVATION CREATEA FIRST-CLASS ENTERPRISE

AND BUILD A CENTURY OLD BRAND

Jilin SSK Electromechanical Co. Ltd. is a manufacturer and service provider specializing in the research,

development, and manufacturing of intelligent poultry slaughtering and deep processing equipment in

China. For many years, the company has been dedicated to the research and development of high-end

poultry processing equipment, promoting the optimization and upgrading of national intelligent poultry

slaughtering and deep processing equipment. The company’s core development strategy is based on

technological innovation, leveraging its own resources, integrating advanced technologies from around the world, and continuously innovating and accumulating technology to provide advanced poultry processing equipment and technology, as well as professional, meticulous, and efficient services to customers, sharing success with them and advancing together with the industry. The company’s products mainly target

medium and large poultry slaughtering and food (meat, seafood, pasta, vegetables, and egg products) deep processing enterprises both domestically and internationally. With personalized design solutions, high-

quality products, and excellent after-sales service, the company has earned the trust of its customers. Its products are sold in more than twenty provinces, municipalities, and autonomous regions across the

country and are also exported to ten countries and regions in Asia, Africa, and Europe.

The company has been recognized as a high-tech enterprise, a national specialized and innovative "little giant" enterprise, one of the top ten meat processing equipment enterprises in China, and the Jilin

Province Poultry Processing Equipment Technology Innovation Center. It is also a drafting unit for poultry processing equipment and processing technology standards. In recent years, the company has completed multiple scientific research projects, including the "Research and Development and Integration

Demonstration of Key Automation Equipment for Poultry Slaughtering" project under the National Key R&D Program during the 12th Five-Year Plan and the "Research and Development and Demonstration of

Poultry Automation Cutting Technology and Equipment" project under the 13th Five-Year Plan, both of which have passed acceptance.

The company has jointly established the "Poultry Intelligent Processing Technology R&D Center " with the Chinese Academy of Agricultural Mechanization Sciences. Both parties will work together to carry out

technological innovation activities, promote the improvement of intelligent poultry slaughtering

technology in China, jointly undertake major national scientific and technological tasks, create a shared platform for technological information and resources, and establish a talent management, training, and exchange system to jointly promote the establishment of a cooperative mechanism for industry-

university-research collaboration that fosters positive interaction between knowledge innovation and technological innovation.

As the company’s business continues to expand and customer service demands increase, it has built a

remote monitoring and operation maintenance system. This system mainly consists of an on-site data

collection system, real-time video monitoring system, internet communication system, cloud server,

communication, and expert consultation system. Through this system, the actual operating status of user equipment can be timely presented, sampled, analyzed, and diagnosed, ensuring increased user benefits. Currently, the system has achieved preliminary operation, and the next step will be to collaborate with

relevant research institutions to further deepen the related technologies and service models in the field of remote services, providing users with high-quality, convenient, and efficient services.

While continuously innovating technologically, the company actively participates in the drafting and

formulation of industry standards. Currently, 13 national and ministerial standards have been issued and implemented. The formulation and implementation of these standards have promoted the standardization and normalization of meat processing machinery in China.

Through continuous development and improvement, the company has entered a healthy, harmonious, and rapid development track. The quality of the company’s economic operation has improved year by year, the product R&D system has become increasingly refined, and the product grade and quality have significantly improved. The company is determined to focus on high-end equipment and promote transformation and upgrading, continuously enhancing its core competitiveness.